Mitsui Chemicals Develops Eco-Friendly Admer™ Adhesive Resin

Development of plant-derived Biomass Admer and recycling agent grade to help realize a circular economy

2021.02.18

Mitsui Chemicals, Inc.

Mitsui Chemicals, Inc. (Tokyo: 4183; President & CEO: HASHIMOTO Osamu) has added two new grades to its globally pioneering Admer™ range of polyolefin-based adhesive resins, which are used in multilayer bottles, tubes, films and sheets. Aiming to contribute to the creation of a circular economy, Mitsui Chemicals has developed the environmentally friendly Admer™ EF Series in response to a high level of need among customers and society as a whole. Featured in the new lineup are Biomass Admer, which contains at least 50 percent biomass, and a recycling agent to remedy the degradation in strength, impact resistance and other properties that occurs due to recycling.

Biomass Grade

(Example of layer composition: PE / Admer™ EF / EVOH / Admer™ EF / PE)

Recycling Agent Grade

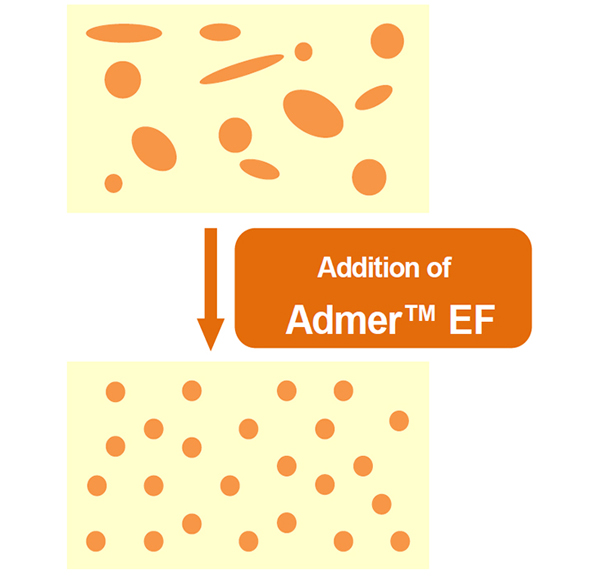

Illustration of polymer sea-island structure

1) Biomass Grade

| Features | Adhesive resin containing at least 50%biomass to help combat global warming Same adhesive strength, moldability and molding appearance as conventional Admer™, making application easy | |

|---|---|---|

| Main Applications | Multilayer bottles | Recommended grade: Admer™ EF BE550 |

| Multilayer tubes | Recommended grade: Admer™ EF BE300 | |

| Multilayer films and sheets | Recommended grade: Admer™ EF BE518 | |

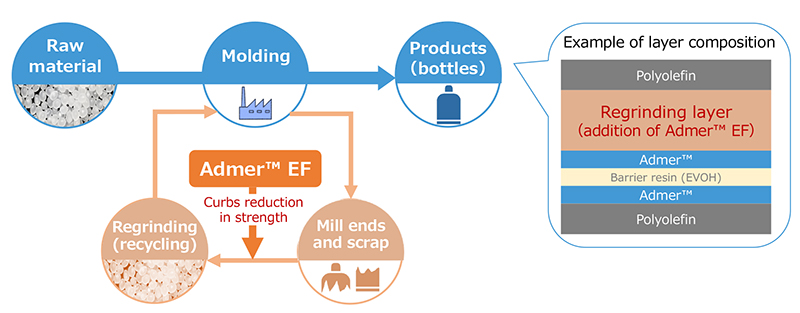

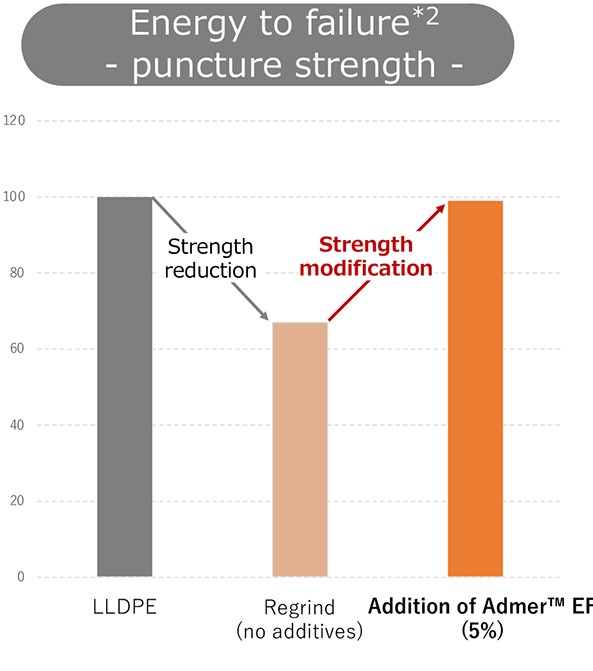

2) Recycling Agent Grade

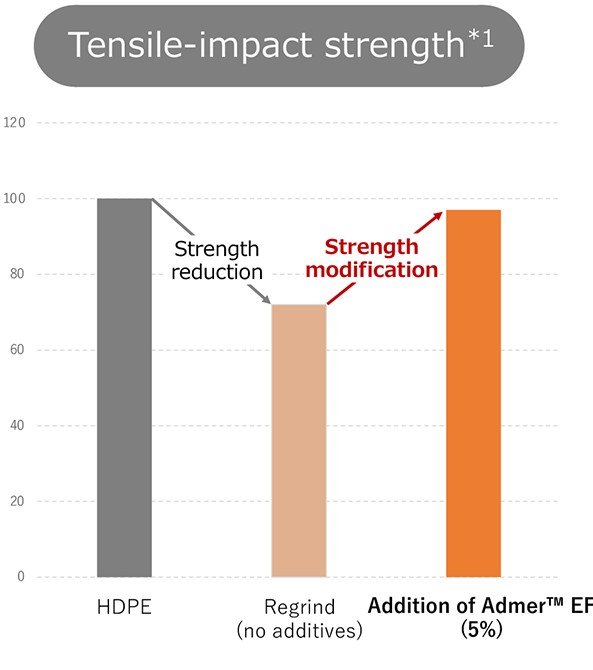

Recent years have seen efforts made to reduce plastic waste by avoiding the generation of this as far as possible. However, a major challenge in recycling mill ends and scrap generated in manufacturing processes has been the degradation in properties such as strength and impact resistance – this caused by the effects of heat on plastic in primary processing, as well as by the presence of other materials in plastic products such as multilayer bottles (see Figure 1). Adding Admer™ EF (recycling agent grade) during the recycling process helps to curb such reductions in strength and impact resistance (see Figure 2). The newly developed grade will therefore make a substantial contribution to promoting a widespread shift to the mechanical recycling of packaging material and other molded plastic items.

[Figure 1: Illustration of recycling process]

[Figure 2: Property enhancement effects of Admer™ EF]

Using ISO 8256 Type 1 test specimens; hammer capacity: 2 J; swing angle: 149.3°

Measured temperature: −20°C; tip diameter: 1 mm; speed: 50 mm/minute