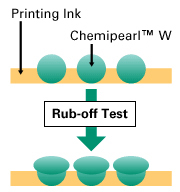

Additives for printing ink, heat sealants

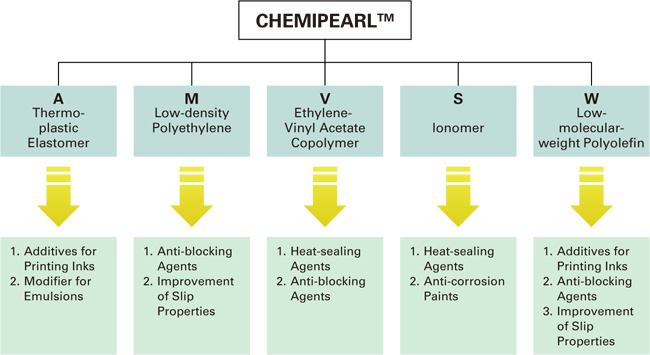

CHEMIPEARL™

Polyolefin-based Aqueous Dispersion

CHEMIPEARL™, which is made of fine particles of polyolefin, uses Mitsui Chemicals’ unique technology and is an environment-friendly aqueous dispersion that does not use emulsifying agents or organic solvents (except for some grades and Products in Development).

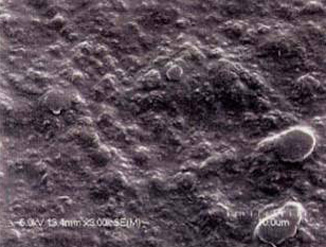

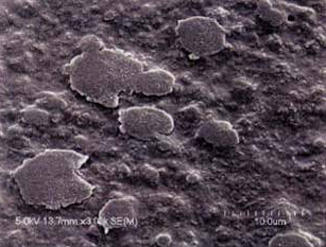

Abrasion resistant Improved slip properties Anti-blocking agent Superior application properties Outstanding heat-sealing properties Hygienic qualities

Applications detail

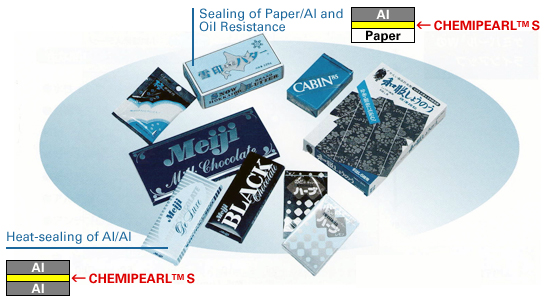

Applications

Characteristics

- Basic information

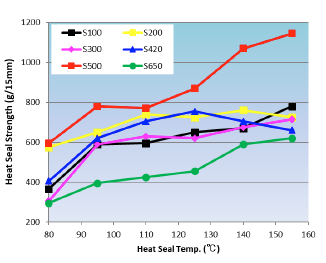

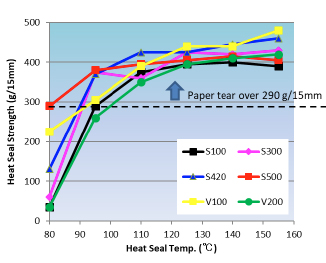

- Details of Characteristics

- Details of Applications

BASIC INFORMATION

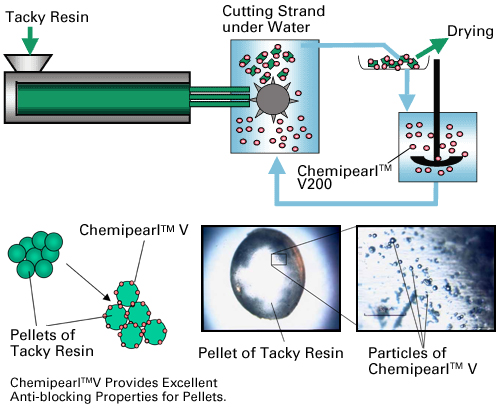

CHEMIPEARL™ is a particulate aqueous dispersion developed by Mitsui Chemicals, Inc. It is a unique product made of fine particles of polyolefins, which were previously considered to be extremely difficult to disperse in water. When compared with widely used aqueous dispersion techniques, CHEMIPEARL™ is unique in that it does not use emulsifying agents or organic solvents, making it highly environmentally friendly. The characteristics of polyolefins, such as its mechanical, water-resistant, and chemical resistant properties, remain intact, making the product ideal for widespread use as printing ink additives, heat sealing for food packaging, adhesives and binders, and anti-blocking agents.